powered by PiQR.io

powered by PiQR.io

Walking into a bakery, the sight of fluffy whipped cream cakes always draws attention. Behind this, food-grade nitrous oxide (E942) plays a key role. As the core propellant for cream foaming, it gives whipped cream a fine texture and light mouthfeel, and is widely used in cake decoration, dessert making, and similar scenarios.

However, it also comes with some controversy. When residual levels exceed the standard, it may have an impact on human health, such as interfering with vitamin B12 metabolism and even causing neurotoxicity.

Currently, different countries and regions have inconsistent regulatory standards for this food additive, which brings challenges to the industry. Understanding these standards and related knowledge is essential for both food enterprises and consumers.

Different regions focus on different aspects when it comes to residual nitrous oxide safety standards. The main international standards are as follows:

European Union: Follows the general food additive regulation (EC) No 1333/2008. This regulation emphasizes that when using nitrous oxide, the necessity of the process must be considered, along with a strict toxicological assessment to ensure that its use does not pose a hazard to human health.

Yhdysvallat: The FDA classifies nitrous oxide as a GRAS (Generally Recognized As Safe) substance. However, this does not mean it can be used arbitrarily. Its usage is limited to the medical and food processing fields, and the relevant operational specifications must be followed during use.

Pressure and Temperature: Under high-pressure conditions and with increasing temperature, the solubility of nitrous oxide will rise, which means more gas may remain in the cream. Therefore, during production, pressure must be reasonably controlled to balance the foaming effect and residual levels.

Foaming Time and Frequency: Frequent use of cream chargers can cause excessive gas to dissolve into the cream matrix, increasing the risk of high residual levels.

Rasvapitoisuus: High-fat cream (e.g., 40% milk fat) has a greater capacity to absorb gas compared to low-fat cream, making it more likely to exceed residual limits.

pH Value and Additives: An acidic environment may accelerate gas release, while emulsifiers can affect foam stability, indirectly influencing nitrous oxide residual levels.

Acute toxicity: Excessive inhalation can cause oxygen deprivation in the body, thereby suppressing the central nervous system and leading to symptoms such as dizziness, nausea, and difficulty breathing.

Chronic hazards: Long-term, low-dose exposure may lead to megaloblastic anemia and cause degenerative changes in the nerves, impairing normal bodily functions.

Acute Toxicity: Excessive inhalation can cause oxygen deprivation in the body, suppress the central nervous system, and lead to symptoms such as dizziness, nausea, and difficulty breathing.

Chronic Hazards: Long-term low-dose exposure may cause megaloblastic anemia, degenerative nerve damage, and impair normal bodily functions.

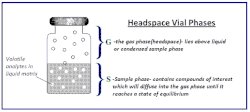

Headspace Gas Chromatography–Mass Spectrometry (HS-GCMS): According to GB/T 43241-2023, the sample is pre-treated by placing the cream sample in a headspace vial, equilibrating it at a certain temperature for a period of time so that nitrous oxide is released into the headspace, and then performing qualitative and quantitative analysis with GC-MS.

Portable Detectors: Suitable for rapid on-site screening and can provide approximate results in a short time. However, their detection accuracy is relatively low, and errors may occur when detecting trace residuals. They are best used for preliminary screening.

Equipment Calibration: Regularly calibrate pressure valves and gas flow meters to ensure accurate injection volumes and reduce the risk of exceeding residual limits due to equipment errors.

Batch Testing: Each production batch should be sampled and sent for testing, and a residual database should be established. Data analysis can help identify issues in the production process and allow timely adjustments.

Obtain ISO 22000 Food Safety Management System certification and establish HACCP critical control points. Set monitoring points at key stages of cream production to ensure nitrous oxide usage and residual levels remain within controlled limits.

Hazardous Goods Packaging Declaration: Pack cream chargers in accordance with relevant regulations, accurately fill in the UN classification number, and affix compliant transport labels.

Food Additive Labeling: The label must contain ingredient statements in both Chinese and English, clearly stating the nitrous oxide content and usage limits so that importers and consumers are fully informed.

Gas Supplier Qualification Review: When selecting suppliers, give preference to manufacturers certified by the FDA or EFSA. Our Like Cream Deluxe, strictly follows all international standards, ensuring gas quality from the source and providing a reliable guarantee for production safety.

Employee Training System: Regularly organize training on operational standards, ensuring employees are familiar with cream charger usage and emergency handling procedures so they can respond quickly and effectively to unexpected situations.

| Kaasutyyppi | Edut | Disadvantages |

| Typpioksiduuli | Excellent foaming effect, fine cream texture; can be used at normal pressures with relatively low equipment requirements | If residual levels exceed limits, it may pose health risks |

| Nitrogen (N₂) | Higher safety | Only 50% of the foaming capacity of nitrous oxide; requires higher-pressure equipment, increasing production costs and operational difficulty |

| Carbon Dioxide (CO₂) | Relatively easy to obtain | May alter the cream’s pH, affecting taste and shelf life |

Now that you know so much about nitrous oxide residual levels in cream chargers, you should have a clearer idea of how to use this cream-enhancing gas safely. Choosing a compliant and reliable product makes this much easier.

From production to delivery, Cream Deluxe cream chargers strictly adhere to domestic and international safety standards, with precise residual control so you don’t have to worry about safety. They are widely applicable—not only for professional bakeries making delicate desserts, but also for DIY home cakes and outdoor picnics. Just a few simple steps and your cream is whipped and ready.

In hot summer weather, cream whipped with our chargers has excellent stability and resists collapse, keeping your creations perfect for longer. If you want to make cream preparation easier and more efficient, try Cream Deluxe cream chargers and experience the convenience and peace of mind they bring.

| Cookie | Kesto | Kuvaus |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 kuukautta | Tämän evästeen asettaa GDPR Cookie Consent -lisäosa. Evästettä käytetään tallentamaan käyttäjän suostumus kategorian "Analytics" evästeille. |

| cookielawinfo-checkbox-functional | 11 kuukautta | Eväste asetetaan GDPR:n evästesuostumuksen mukaisesti tallentamaan käyttäjän suostumus kategorian "toiminnalliset" evästeet. |

| cookielawinfo-checkbox-necessary | 11 kuukautta | Tämän evästeen asettaa GDPR Cookie Consent -lisäosa. Evästettä käytetään tallentamaan käyttäjän suostumus evästeille luokassa "Välttämätön". |

| cookielawinfo-checkbox-others | 11 kuukautta | Tämän evästeen asettaa GDPR Cookie Consent -lisäosa. Evästettä käytetään tallentamaan käyttäjän suostumus evästeille kategoriassa "Muut". |

| cookielawinfo-checkbox-others | 11 kuukautta | Tämän evästeen asettaa GDPR Cookie Consent -lisäosa. Evästettä käytetään tallentamaan käyttäjän suostumus evästeille kategoriassa "Muut". |

| cookielawinfo-checkbox-performance | 11 kuukautta | Tämän evästeen asettaa GDPR Cookie Consent -lisäosa. Evästettä käytetään tallentamaan käyttäjän suostumus kategorian "Suorituskyky" evästeille. |

| viewed_cookie_policy | 11 kuukautta | Evästeen asettaa GDPR Cookie Consent -lisäosa, ja sitä käytetään tallentamaan, onko käyttäjä antanut suostumuksensa evästeiden käyttöön. Se ei tallenna mitään henkilötietoja. |