powered by PiQR.io

powered by PiQR.io

As a global leader in cream charger manufacturing, Cream Deluxe is committed to integrating the technological potential of nitrous oxide (N₂O) with the evolving needs of the food industry. This article provides a comprehensive analysis of N₂O’s applications in food production, its technical principles, regulatory framework, and future trends, demonstrating how it has become a driving force behind modern food industry advancements.

Nitrous oxide (N₂O) is widely used in the food industry for cream whipping, food preservation, molecular gastronomy, and process optimization. Its high solubility, low-temperature inertness, and dual functionality make it an ideal foaming agent and preservative gas, enhancing product quality and extending shelf life. With the rise of clean-label products, smart manufacturing, and sustainable packaging, N₂O is driving the food industry toward greater efficiency, safety, and sustainability.

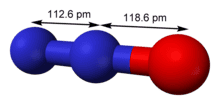

Nitrous oxide (N₂O) is a colorless, slightly sweet-smelling inorganic gas with stable chemical properties and high solubility. Its molecular structure, consisting of two nitrogen atoms bonded to an oxygen atom, makes it highly inert at room temperature while allowing it to rapidly release gas and form uniform microbubbles under specific pressure and temperature conditions. These properties make it an ideal physical foaming agent and preservation medium in the food industry.

N₂O’s role in cream processing has expanded beyond traditional baking to coffee chains, ready-to-eat desserts, and home applications.

In MAP applications, N₂O works synergistically with CO₂ and N₂ to displace oxygen, slowing microbial metabolism and fat oxidation.

N₂O has moved beyond traditional foaming and is now a key tool for textural innovation in molecular gastronomy.

N₂O has expanded from being solely a foaming agent to a multifunctional processing aid.

As a food additive (INS 942), N₂O usage is subject to stringent global regulations:

Cream Deluxe ensures compliance through three key measures:

With rising consumer demand for additive-free products, N₂O is poised to replace chemical preservatives (e.g., potassium sorbate) and synthetic foaming agents, accelerating the clean-label movement.

N₂O can be incorporated into biodegradable materials (e.g., PLA, collagen-based films) to develop innovative MAP solutions. Harvard University has pioneered a pH-responsive controlled-release film that regulates preservative diffusion via N₂O release.

With rising demand for ready-to-eat foods in Southeast Asia and Africa, N₂O holds significant potential in pre-packaged meal aeration and portable cream dispenser applications.

As an industry benchmark, Cream Deluxe leads the market through four key advantages:

The history of N₂O’s application in the food industry is a journey from laboratory discovery to global industrial integration. As consumer expectations evolve, regulations tighten, and technological innovation accelerates, Cream Deluxe remains committed to advancing food production efficiency, safety, and sustainability through N₂O.

Try Cream Deluxe’s cream chargers today!

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |